Double piston double working positions continuous screen changer

When we produce the product with plastic extrusion machine, high quality of the raw material are required, but usually ,we do not use the virgin material but reclaimed material, and there are impurities in the reclaimed materials, to ensure the high quality of our products, we must filter the impurities in the raw material by using a screen changer/melt filter. compared with the tradtional screen changer, our double piston double working position screen changer make a perfect performance.

1, improve the quality of the raw material , to further improve the quality of the final products.

2, without stop the working extrusion machine when replace the screen , thus save the labor interfer and power consumption and increase the production capacity in the same period.

3, reasonable price an easy installation and operation and maintain.

This kind of double piston double working position screen changer is consists of the main body of the screen changer, the hydraulic station, and electric cabinet.

Technical Data

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-155 | Screen wrapped on the piston(300*65) | 195 x 2 | 14 | 300-800 |

DHZ-2-230 | Screen wrapped on the piston(420*100) | 420 x 2 | 14 | 400-1000 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | square screen | 900x2 | 14 | 2000--6000 |

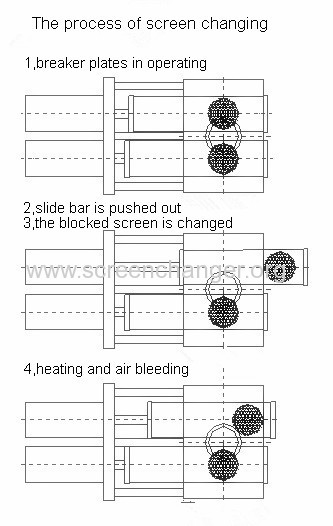

How to work

The double piston Screen Changer allows for filtration of most all polymers without interrupting production during a screen change. The Screen Changer consists of two pistons with each containing a filter cavity. When a screen change is required, one of the pistons is moved out of the housing while the other remains in the operating position. The dirty screen pack is removed and replaced with a new one. The piston is then moved back into the housing to its venting stages before resuming operation. These steps are then repeated for the other piston. This concept allows for continuous filtration with no interruption or loss of production

Applications

.sheet

.coating

.pipe

.compounding

.wire and cable

.tubing

.textiles(fibers and nonwovens)

.EVA, hot melt adhesive and PSA

.pelletizing(strands and underwater)

.recycling of most polymers

.blown film and cast film

.corrosive and degradable materials

.Textiles (fibers and nonwovens)

almost all polymers recycling

The double piston double working position screen changer applied for the extrusion lines