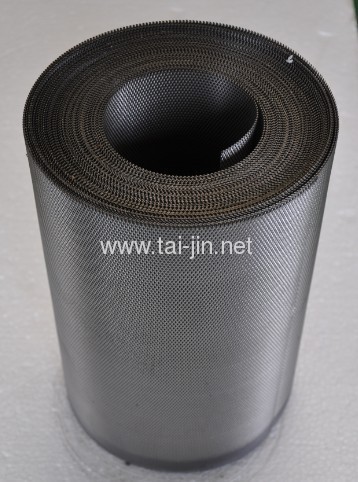

MMO Mesh Ribbon Anode

Mixed Metal Oxide (MMO) Mesh is a durable anode designed for Impressed Current Cathodic Protection systems of steel structures and steel reinforcement concrete, it proves a good and effective way to protect the rebars embeded in steel concrete against corrosion.

Product Details

1. Substrate & Coating

1) Base Metal: Titanium ASTM B265 Grade 1

2) Coating: Mixed Metal Oxide-IrO2+Ta2O5 Base

2. Specification and Parameters:

1) Other specification can be available as client's requirement.

width (mm) | length (m) | thickness (mm) | Diamond Dimension (mm) | Current Rate (mA/m) | surface area per coil (m2) | Net weight per coil (Kg) | Gross weight per coil (Kg) | Nominally dimension per coil (mm) |

10 | 76 | 1.3 | 2.5x4.6 x0.6 | 2.80 | 1.85 | 1.4 | 1.6 | 410x410 x22 |

13 | 76 | 1.3 | 2.5x4.6 x0.6 | 3.50 | 2.40 | 1.8 | 2.0 | 410 x410 x25 |

19 | 76 | 1.3 | 2.5x4.6 x0.6 | 5.28 | 3.60 | 2.7 | 2.9 | 410x410 x41 |

20 | 76 | 1.3 | 2.5x4.6 x0.6 | 5.30 | 3.80 | 2.8 | 3.0 | 410x410x43 |

1220 | 76 | 1.98 | 25x50 x0.89 | 37.8 | 92.9 | 43 | 43 | 1400 x650 x650 |

1220 | 76 | 1.98 | 34x76x0.89 | 24.4 | 92.9 | 33 | 33 | 1400 x650 x650 |

2) Substrate

Composition Titanium,Grade1 per ASTM B265 | Coefficient of thermal expansion 8.7×10-5 |

Coefficient of thermal expansion | 8.7×10-5/ok(0.0000048/in/in/ok) |

Thermal conductivity at 20℃ | 15.6W/m-ok(9.0BTU/hr/ ft2/oF/ ft2) |

Electrical | 0.000056 ohm-cm(0.000022 ohm-in) |

Modulus | 105 GPa(14,900,000 PSI)minimum |

Tensile | 240 MPa(35,000 PSI)minimum |

Yield | 170 MPa(25,000 PSI)minimum |

Elongation | 24% minimum |

3) Conductor Bar

Width(mm) | 6.35 | 12.7 |

Length(m) | 76, 100,152 or as your request | |

Weight per meters(Kg) | 0.051 | |

3. Quality Assurance and Control

Strict quality procedures are followed throughout the whole process from raw materials to finished products to ensure coating adhesion and loading.

1) Chemical Composition- ASTM B265 Gr1

Element | Content % |

Nitrogen | 0.03 Max |

Carbon | 0.08 Max |

Hydrogen | 0.015 Max |

Iron | 0.2 Max |

Oxygen | 0.18 Max |

Residual(each) | 0.1 Max |

Residual(total) | 0.4 Max |

Titanium | Balance |

2) Visual Coating Uniformity, Color and Scratch

3) Coating adhesion

Three Steps

First, feeling the surface of tubular anodes in a pair of white gloves to observe

whether black mark is left on the gloves

Second, paste with transparent tape to observe whether black mark is left on the

Tape

Third, bend the ribbon to observe whether the coating fades

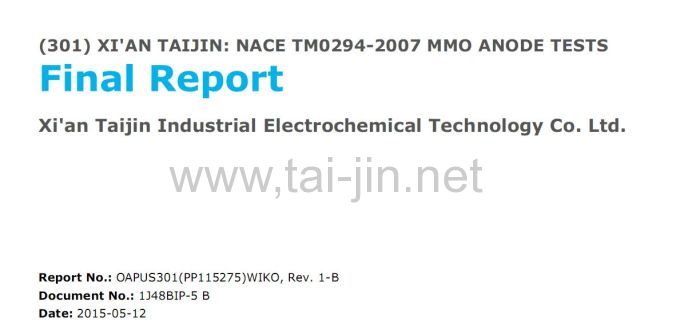

4) Accelerate Life Test

NACE standard TM0294-2007, 15000A/m2, 1mol/l Na2SO4

4. The 3rd Party Quality Test from USA DNV

5. Prodcuts

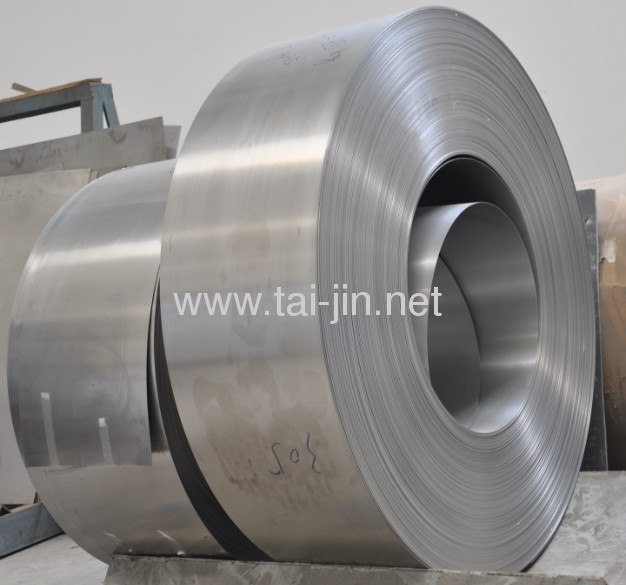

Raw Materials

Half-finishedProducts

Finished Items

Packages

Company Information

1. Introduction

1) Founded in 1998, our Company is a major supplier and manufacturer of MMO & platinized titanium anodes,

cathodes, nonferrous metals and deep-processed titanium products and Electrolyzing Devices.

2) We have 3 large workshops covering 50 acres with a staff force of above 200 and strong producing capability.

3) ISO certified companies complying to the ISO 9001:2008

4) The third party test certification

a) MMO Ribbon Anode and MMO Mesh Ribbon Anode Performance Test from Det Norske Veritas

Inc. under the standard of NACE TM0108 and NACE TM0294

b) Production Assessment from Bureau Veritas Certification

c) SGS Verified Gold supplier of titanium anodes

5) Joint verture

a) Qingdao Suirui Marine Enviroment Engineering Co. Ltd.

b) Wuhan Xingda Technology Engineering Co. Ltd.

c) Corrpro Companies,

d) Siemens Water Technologies

e) Savcor Tempo Oy

f) Cathelco Limited

g) Hama Trading & Contracting Co.(Kuwait) and so on

2. Workshop and laboratory

Machining shop

Precise Temperature Control Resistance Furnace

Accelerated Life Test

Coating Thicknes Test (SEM)

Helium Mass Spectrometer Leak Detector

3. Certificates

ISO9001:2008 Quality Certificate

SGS Golden Supplier

BV Production Assessment Certificate