1. Technical specs for metal buildings ( made of steel frame ) :

Specification | Structure type | Heavy steel structure |

Design standard | AISI / ASTM / BS / DIN / GB / JIS | |

Length | With customer's requirement | |

Width | Single span , double-span , multi-span | |

Height | With customer's requirement | |

Components | Bolt | Steel grade 45 |

Column | Q235B , Q345B welded H section steel | |

Beam | Q235B , Q345B welded H section steel | |

Tube | Steel Q235B , Q345B | |

High strength bolt | Cr 40 , 10.9S , 9.8S , galvanization | |

Sleeve | Steel Q235B , Q345B , galvanization | |

Purlin | Q235B C channel or Z channel , galvanization | |

Roof & Wall panel | Sandwich panels , Corrugated steel sheet , FRP sheet |

2. Our Factory:

We were founded and located in Shandong Province, China. We have fixed assets of 180 million RMB and a workshop plant area of more than 200, 000 Square meters. Our manufacturing base covers 360, 000 square meters. In addition, we have more than 960 employees, including 110 intermediate and senior technical staff members. Besides, we have our own installation and construction teams. We also have abundant financial resources and advanced equipment, including H-TYPE and BOX-TYPE steel structure production lines, full-range impeller blasting equipment, production lines of rack and truss, C-TYPE and Z-TYPE steel forming machines, various kinds of machine tools, drilling machines, folding machines and physical and chemical detection equipment.

3. Project case- Qilu Petro-chemical Heavy Steel Workshop:

Size: 55000 square meter workshop, Single Span 39m, eave height 18m, mainly loading bear steel member over 100Ton, totally quantity of steel 6000Ton.

Steel Column: Q345B Four tube lattice column. Painted: 120um epoxy zinc painted.

Roof Structure: Q235B Pipe Truss Structure. Painted: 120um epoxy zinc painted.

Crane Beam: Q345B H section Steel Beam. Painted: 120um epoxy zinc painted.

Secondary Structure

Roof Horizontal Bracing: Q235B Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Wall X Cross Bracing: Q235B Double Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Tie Beam: Q235B Welding Pipe, Painted: three layer white color anti-rust Alkyd painted.

Roof Purlin: Galvanized C section steel

Wall Purlin: Galvanized C section steel

Steel Rod: Galvanized Steel Rod.

Panel system

Roof: 0.5mm Single Color sheet

Wall: 0.5mm Single Color sheet

4. We found international surface treatment system for the metal buildings ( made of steel frame ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for metal buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

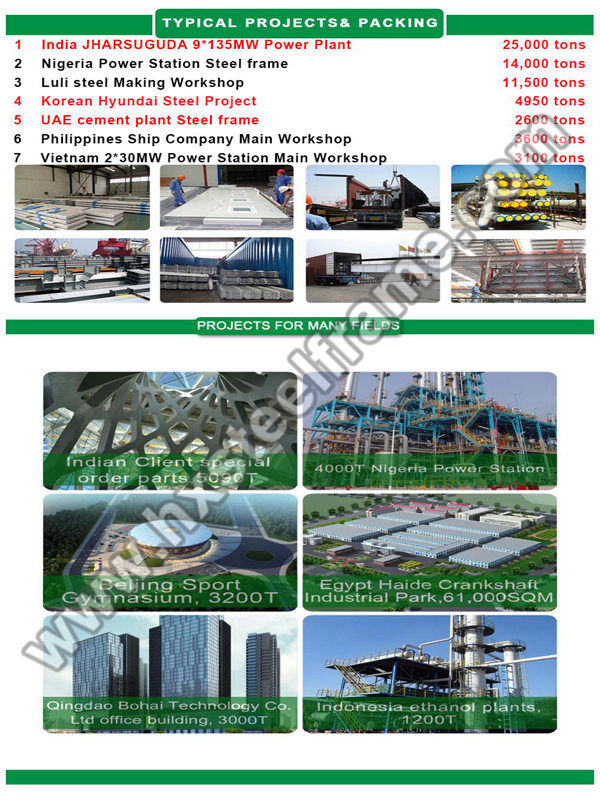

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How can I install these metal buildings ( made of steel frame ) together as a building after cargo arrived ?

Normally, most clients choose to install the steel building structure frame themselves or ask local technical engineer for further instruction.

If local technical support is not available or cost too much, we could also provide technical support engineer cross over-seas for installation guide even with our installation engineering team.

2) How to maintain my metal buildings ( made of steel frame ) years of using ?

metal buildings ( made of steel frame ) are built for long-time, reliable, steady usage purpose, the maintenance process is easy to operate and complete, most our product can live 10-15 years with minimal maintenance work like gel filled and paint spray. We will keep tracking the usage performance of our products and provide maintenance instruction for our clients.