1. Products description for the Steel building ( made of offshore structural steel ) :

Main Steel | |

Steel Beam Column | Q235B , Q345B |

Secondary Steel | |

Tie Bar | Q235B |

Purlin | C and Z purlin |

Bracing | Q235B |

Accessories | |

Surface | Painted or Hot Dip Galvanized |

Door | Rolling Up Door or Sliding Door |

Window | PVC or Aluminum Alloy |

Roof and Wall Panels | Corrugated Steel Sheet , EPS Sandwich Panel , Rock Wool Sandwich Panel , PU Sandwich Panel |

Others | |

Service | Design , Fabrication and Installation |

We can offer quotations according to customers' drawings and requirements , free design drawings and detailed installation drawings . | |

Design software : Auto CAD , PKPM , MTS , 3D3S , TArch , Tekla Structures ( X steel ) V12.0 , etc | |

Packing | main steel frame with 40 OT roof and panel load in 40 HQ Or According To Customer Requirement |

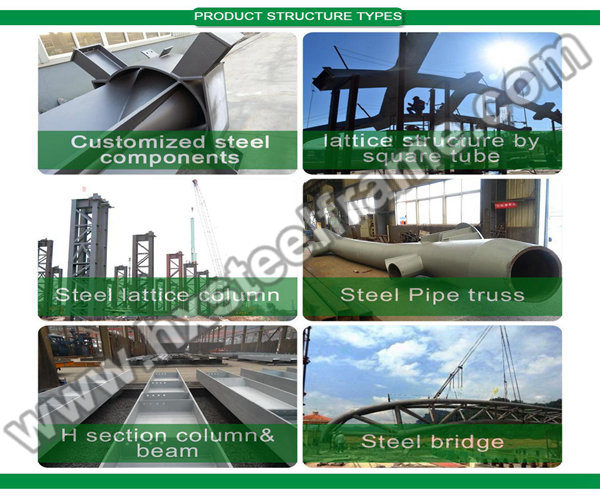

2. We are specialized in design and production of prefab steel building, heavy Structure, workshop& warehouse etc. :

We have a strong technical team. We have 960 employees, 80 of them are professional designers and engineers with rich experience in designing and producing. Base in our good management, good quality and excellent after selling service, we got ISO9000, 14000, 18000 by BV France, AWS welder, EN welder, CE certificate, SGS. It brought much business chance to us.

Depending on our professional engineers, most of our products got the design patent. Therefore, our products are not only welcomed by our homeland customers, but also popular among many foreign countries, such as Australia, Qatar, Iran, Sudan, Angola and East-south Asia, Middle East and other regions, etc.

3. Some of OUR WORKSHOP/ WAREHOUSE PROJECTS:

1) AREVA Transformer Factory Project:

Covering an area totaled 33, 842 sq.m, the program consumed steel in 4299 tons, the column height is 31-33 m, and the inside is installed with the bunk bed traveling crane with the maximum hoisting capacity in 400 tons.

2) NEW ZEALAND Barns / Grain Warehouses:

light gauge steel structure with cold bended profiles.

3) BOLIVIA Cement Plant:

Steel consumption: 3, 655 tons in the first phase, 7200 tons in the second phase.

4) LDK Polysilicon Public Project:

Was generally contracted by FLR CO., LTD, the total steel consumption volume for Phase I project reached over 3000 tons and this program was in a high-rise steel structure of 4-7 floors.

4. We found international surface treatment system for the Steel building ( made of offshore structural steel ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for Steel building ( made of offshore structural steel ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How to control the quality of your Steel building ( made of offshore structural steel ) ?

a. quality of the design: think about possible problems in advance and provide a high quality design solution.

b. quality of the raw material: choose the qualified raw material from the top steel mill in China.

c. quality of the production: precise manufacturing technique, experienced workers, strict quality inspection.

2) How to deal with quality problems of your Steel building ( made of offshore structural steel ) ?

Warranty is 2 years. Within the warranty period, we will responsible for all quality problems caused by production.