1. Steel building ( made of heavy metal manufacturing ) main components description :

1 ) Mainly made by H - section and box girder .

Wide flanges make H - beam have a higher lateral stiffness fit for compression member .

Flanges of H - section with same thickness parallel with one another have strong resistance to bending , easy to composite and joint with other component for your prefab steel structure workshop .

2 ) Support System

Support system of prefab steel structure workshop mainly consist of purlin , cross bracing and angle brace made by Z - section , C - section or angle , allot the payload of column and pillar , transfer the loading to whole frame .

Support system makes the frame structure stand as a unity ; improve the solidity and stabilization of frame itself .

3 ) Roof and wall panel system

Roof and wall panel system mainly made of color steel or color steel sandwich panel .

Roof and wall panel system connected by self-tapping screw , easy and fast to assemble .

Good mechanical property as well as bearing capacity of prefab steel structure workshop .

Multiple color and surface finishing available meet your customization requirement and preference for prefab steel structure workshop .

2. About our company:

1) We have a group of professional engineers, most of whom has more than 10 years' experiences in architecture field.

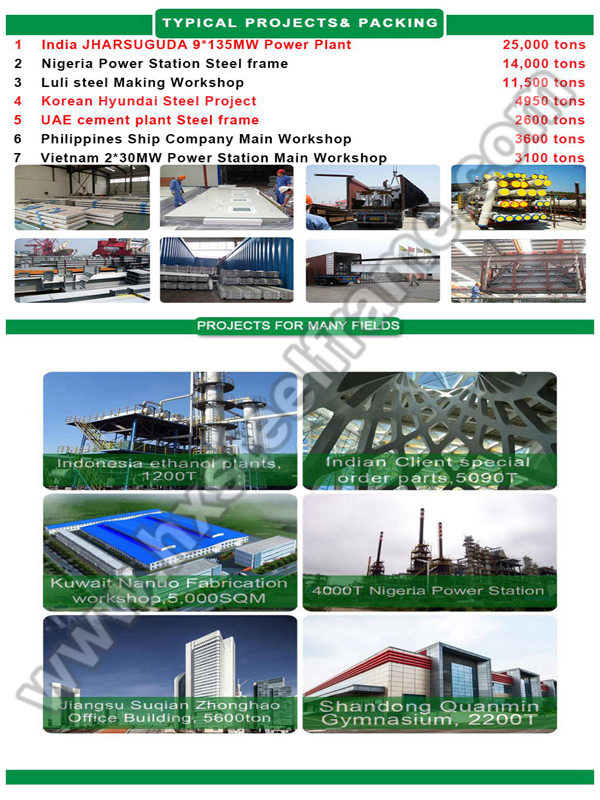

2) Established for more than ten years, our company has got a various of experiences in all kinds of steel structure& steel building design, manufacture, installation and so on. The work staffs have excellent skills. Some of them had helped customers to install the warehouse around the world.

3) We have the capacity of annually 200,000 tons steel structure. We also have possessed more than 300 sets of large precise and advanced processing equipment, including large gantry planning machines, automatic submerged arc welding machines, assembling machines, shot blasting machines and so on.

3. Project case- Argentina Wugan warehouse, 2012:

Description: This project comprises a high specification industrial unit, factory and warehouse for a company producing electronic systems for industry. The building features an integrated two storey office facility, composite panel wall cladding and a curved roof with a standing seam system, barrel vault roof lights and a 10t travelling crane.

The client choose us after visited 6 China suppliers, when they came to our factory, we are producing and delivering steel structure for 9 countries, more than 20 containers are stuffing for 4 countries. No need more words, seeing is believing!

4. Our service for the product of Steel building ( made of heavy metal manufacturing ) :

Pre-Sales Service

1) Consultant service( Answering client' s questions)

2) Primary design plan( Free)

3) Assisting client to choose suitable construction plan

4) Price calculation

5) Business & technology discussion

Sale Service

1) Submission of support reaction data for foundation

2) Submission of construction drawing

3) Providing requirements for embedding

4) Construction Manual

5) Fabrication & Packing

6) Statistical table of material

7) Delivery on time

8) Other requirements by Clients

After-Sale Service

1) Service of installation Supervision

2) Instruction for using after installation completed

5. Packaging & Delivery for Steel building ( made of heavy metal manufacturing ) :

Packaging Details

steel structure factory packaging:

1) steel structure: steel frame or pallet packing

2) panel: plastic film packing

3) Bolts: steel box packing

4) loaded into 40' HQ

Delivery Time

Shipping depended on order quantity or to the customer' s requirements

6. FAQ:

1) Common type of the industrial building you supply ?

Portal frame is the usual type in the industrial workshop and warehouse shed, other types like lattice structure, space structure, etc also could be designed and manufacturer as per customers request.

2) What is the quality grade of the Steel building ( made of heavy metal manufacturing ) ?

Q345 is used for main steel structure, Q235 is used for secondary steel structure.

Also we could use international steel as per your demand if order qty is big enough.

3) How about the delivery time for your Steel building ( made of heavy metal manufacturing ) ?

Usually, within 30-45 days after the order confirmed, also depends on the fabrication quantity.