Main Technical Parameter of Submerged Arc Furnace

Transformer rated capacity

Transformer primary voltage

Transformer secondary rated voltage

Transformer secondary rated current

Electrode diameter

Furnace hearth diameter

Furnace heart depth

Furance shell diameter

Furnace shell height

Electrode pole diameter

Taping hole quantity

Smoke hood diameter

Electrode stroke

Electrode lifting speed

Electrode copper watt

Oil cylinder

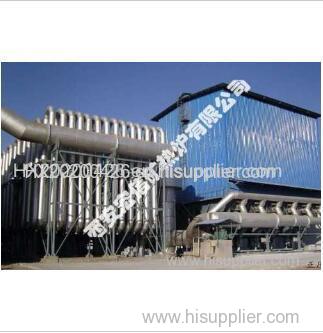

Furnace introduction

submerged melting furnace, is also known as electric arc furnace or resistance furnace,

it is mainly used for the reduction of smelting ores, carbon reductants and solvents etc.

It is mainly for production of ferrosilicon, ferromanganese, ferrochromium, tungsten iron,

Equipment introduction

Submerged arc furnace is alos known as electric arc furnace or resistance electric furnace.

It is mainly used to reduce smelting ore, carbonaceous reducing agent and solvent etc. Mainly

adapt to production of ferromanganese, ferrochrome, silicon manganese alloy and other ferrous

alloy.

Product Description

Electric arc furnace is an electric furnace for smelting ores and metals at high temperature

produced by electrode arc. the energy is very concentrated, and the temperature of arc

region is above 3000C . For smelting metals, EAF is more flexible than other steelmaking

furnace.

Main Technical parameter

1 Transformer rated capacity

2 Transformer primary voltage

3 Transformer secondary rated voltage

4 Transformer secondary rated current

5 Electrode diameter

6 Furnace hearth diameter

7 Furnace hearth depth

8 Furnace shell diameter

9 Furnace shell height

10 Electrode pole diameter

Furnace outside circulating water system

1 Water pump

2 Water pump (TR)

3 Cooling tower ( closing type )

4 Water softening plant

5 Water distribution network

6 Auxiliary facilities for water pump house

7 Water pump of silica stone washing

Construction

Submerged arc furnace used for steelmaking consists of a refractory lined vessel, usually water

cooled in large size, convered with a retractable roof, and through which one or more graphite

electrodes enter the furnace, The furnace is primarily split into three sections :

Equipment suplly list

1 Mechnical parts

Furnace body ( upper shell and lower shell )

Tilting mechanism

Water cooled roof and water pipe

Roof lifting and rotating mechanism

Electrode arms and traveling mechanism

EBT platform

Rotation frame locking device

Feeding hopper ( on the roof )

Electrode nippling station

Cooling water distributor

2 Electrical parts

Transformer

High voltage system

Short network

Lower voltage system

PLC automation and HMI system

3 Auxilliary items

Compressed power pack

Lubrication station

Water cooled door oxygen lance

oxygen carbon wall lance

steel temperature / measuring thermometer

Component

Furance shell / roof/ lining

Large current system

Water cooling system

Fume exhausting system

Dedusting system

Dedusting system

Electrode shell

Electrode lifting system

Charging / discharging system

Electrode holder

Arc burner

Hydraulic system

Transformer

1) Mechanical part

Furance body

Low hood

Fume/ gas delivery tube

control system

Hydraulic system

Water cooling cable

Hydraulic system

Steel tapping system

2) HV electrical part

HV power supply

LV power supply

V electrical control system

Electrode lifting system

Supply list

Furnace body ( upper shell and lower shell )

Tilting mechanism

Water cooled roof and water pipe

Roof lifting and rotating mechanism

Electrode arms and traveling mechanism

EBT platform

Rotation frame locking device

Equipment list

Three phase transformer

High voltage cabinet

Low voltage control cabinet operation platform

Furnace body

Furnace shell

Furnace lining

Water cooling smoke hood

Smoke pipe

Tapping smoke evacuation system

Short net

Copper tube

Water cooling cable

Water cooling compensator

Copper tile

Copper bar

Hanging and stainless steel bolt

Equipment components

Furance shell / roof / lining

Large current system

Water cooling system

Fume exhausting system

Dedusting system

Electrode shell

Electrode lifting system

Charging / discharging system

Electrode holder

Arc burner

Hydraulic sytem

Transformer

1 Mechanincal part

Furnace body

Low hood

Fume gas delivery tube

control system

Hydraulic system

Steel tapping system

2 Electrical part

HV power supply

LV power supply

V electrical control system

Electrode lifting system

Main Technical Parameter

Transformer rated capacity

Transformer primary voltage

Transformer secondary rated voltage

Electrode diameter

Furnace hearth diameter

Furnace hearth depth

Furnace hearth diameter

Furnace shell height

Electrode pole diameter

Furnace shell height

Taping hole quantity

smoke hood diameter

Electrode stroke

Electrode lifting speed

Electrode copper watt

Oil cylinder

Oil pipe net

Pneumatic system

Ladle car

Electric single crane

Circulation charging machine

Batching system

Batching bin

Electronic weighing hopper

Belt machine and barcket