Ningbo Yinzhou Hongyong Machinery Factory specializes in the development, production, and sales of precision metal and plastic parts products. We provide services such as Stamping,Drilling,Forging,Tapping,Gear cutting,Wire EDM,CNC Turning. Since its establishment, our high-tech team and excellent service have enjoyed a high reputation in the domestic market. The materials we use include Plastic,Brass,Stainless Steel,Alloy,Carbon steel,Titanium,Iron,Cold rolled sheet,Chrome steel,Steel,Aluminum,Copper, etc. There are surface treatment methods such as Powder coating,polishing,Vacuum plating,Titanium nitriding,Nickel plating,Ion nitriding,Electrolytic polishing,Gold plating,Sandblasting,heat treatment,Oxidation,Zinc plating.

We have obtained certifications such as CE, RoHS, GS, ISO9001, etc. Our products are widely used in fields such as oil&gas exploration,automation industry,Power and energy,hardware tool,medical device industry,auto and motorcycle accessory,aerospace industry. Our precision machinery includes Hydraulic bending machine,Punch press 6.3 to 160 T,Milling machine,Hydraulic shearer,Assembly line,Laser cutting machine and others. Our products have been exported to more than 30 countries, including the United States, South Korea, Russia, and Niue,Czech Republic,Moldova,Guinea,United States of America. We always take pride in maintaining a high-quality spirit.

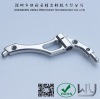

carbon steel cnc machined part:

Machine: 3/4/5 axis CNC Machining Center

Roughness: Ra0.2-Ra3.2

Tolerance: 0.005~0.05mm or refer to drawings strictly

Main Process: Turning / Milling

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

30% deposit ,70% payment aganist B/L

This is our workshop and equipment

carbon steel cnc machined part---FAQs Guide

1.What are the common materials used for carbon steel cnc machined part?

2.Is carbon steel cnc machined part suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

3.What is the role of CNC machining parts in the manufacturing industry?

4.What is the machining accuracy and repeatability of carbon steel cnc machined part to achieve assembly and interchangeability?

5.How do carbon steel cnc machined part manage supply chain and inventory to ensure timely delivery and production planning?

6.How can carbon steel cnc machined part adapt to different hardness and processing requirements of materials, such as steel or plastic?

7.About carbon steel cnc machined part,Where can I get product&price information?

8.Can the size and shape of carbon steel cnc machined part be customized according to needs?

9.How can carbon steel cnc machined part cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

10.How can carbon steel cnc machined part cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

11.How can we ensure our information should not let third party to see our design?

12.Are carbon steel cnc machined part suitable for special surface treatment or coating requirements? Such as wear resistance or corrosion resistance

13.How can carbon steel cnc machined part meet the needs of rapid prototype manufacturing and small batch production?

14.Are there carbon steel cnc machined part suitable for the manufacturing of special precision measurement and calibration equipment, such as microscopes or particle size analyzers?

15.Is carbon steel cnc machined part suitable for applications in high-speed motion and vibration environments, such as automotive engines or machine tools?

16.How can carbon steel cnc machined part meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

1.What are the common materials used for carbon steel cnc machined part?

Titanium, Aluminum, Stainless Steel, Copper/Brass, Iron, any types of alloy

2.Is carbon steel cnc machined part suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

Yes, carbon steel cnc machined part are suitable for manufacturing parts required by special industry standards and regulations, such as aerospace. CNC machining is a precise and accurate process that can produce parts with tight tolerances and complex geometries. It is also capable of producing parts with high levels of repeatability and consistency, which is essential for parts used in the aerospace industry.

3.What is the role of CNC machining parts in the manufacturing industry?

Improving machining accuracy and quality,Improve production efficiency and efficiency

4.What is the machining accuracy and repeatability of carbon steel cnc machined part to achieve assembly and interchangeability?

For machine tools with general machining requirements, the repeated positioning accuracy is generally required to be less than or equal to 0.005mm.

5.How do carbon steel cnc machined part manage supply chain and inventory to ensure timely delivery and production planning?

We are centered on customers and always pay attention to customers' needs for carbon steel cnc machined part products.

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

6.How can carbon steel cnc machined part adapt to different hardness and processing requirements of materials, such as steel or plastic?

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.

7.About carbon steel cnc machined part,Where can I get product&price information?

Send us e-mail , we will contact you as we receive your mail.

8.Can the size and shape of carbon steel cnc machined part be customized according to needs?

Yes, carbon steel cnc machined part can be customized according to the customer's needs. CNC machining can produce parts in a variety of sizes and shapes, including complex geometries. The customer can provide a design or drawing of the desired part, and the CNC machining shop can use the design to create the part.

9.How can carbon steel cnc machined part cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

Reduce the cutting force to the minimum;It is to enhance the static rigidity of the tool system or fixture with the workpiece as much as possible

10.How can carbon steel cnc machined part cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

We have established a good reputation and reliable partnerships within the carbon steel cnc machined part industry.

1.detailed design and modeling of the parts are required

2.Programming is a very important step in the machining process of CNC machine tools

11.How can we ensure our information should not let third party to see our design?

We are willing to sign NDA effect by customer side local law and promising to keep customers data in high confidential level.

12.Are carbon steel cnc machined part suitable for special surface treatment or coating requirements? Such as wear resistance or corrosion resistance

Yes, carbon steel cnc machined part are suitable for special surface treatment or coating requirements. Depending on the application, CNC machined parts can be treated with a variety of coatings, such as anodizing, electroplating, powder coating, and painting. These coatings can provide additional protection against wear and corrosion.

13.How can carbon steel cnc machined part meet the needs of rapid prototype manufacturing and small batch production?

We are centered on customers and always pay attention to customers' needs for carbon steel cnc machined part products.

1.When we use CNC for small batch processing, we need to control the drilling of components well

2.When we use CNC for small batch processing, we need to control the turning of components well

3.When we use CNC for small batch processing, we need to control the milling and cutting angles of the components

4.When we use CNC for small batch processing, we need to control the angle of the slotting process of the components

14.Are there carbon steel cnc machined part suitable for the manufacturing of special precision measurement and calibration equipment, such as microscopes or particle size analyzers?

Yes, carbon steel cnc machined part can be used to manufacture special precision measurement and calibration equipment. CNC machining is a process that uses computer numerical control (CNC) machines to cut and shape materials into precise shapes and sizes. CNC machining can be used to create parts with tight tolerances and intricate details, making it ideal for precision measurement and calibration equipment.

15.Is carbon steel cnc machined part suitable for applications in high-speed motion and vibration environments, such as automotive engines or machine tools?

Yes, carbon steel cnc machined part are suitable for applications in high-speed motion and vibration environments. CNC machining parts are designed to be precise and durable, making them ideal for use in high-speed and vibration environments. CNC machining parts are also able to withstand high temperatures and pressures, making them suitable for use in automotive engines and machine tools.

16.How can carbon steel cnc machined part meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

Before preparing the CNC turning process, we need to first confirm the geometric shape and size of the parts to be processed, which requires accurate calculations. For complex shaped parts, CAD software can be used for design and drawing, and then extract the contour and control lines of the parts to be processed. Through these control points, the machining path can be confirmed, and then the CNC machine tool plan and program can be set up

.jpg)

.jpg)