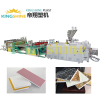

Introduction of PVC foam sheet production line:

Main equipmens of the pvc foam board production line

1. SJZ 80/156 conical twin screw extruder

2. Calibration vacuum system

3. Cooling tank and bracket

4. Haul-off machine

5. Cutting machine

6. Board stacker

PVC foam board applications:

Main equipmens of the pvc foam board production line

1. SJZ 80/156 conical twin screw extruder

2. Calibration vacuum system

3. Cooling tank and bracket

4. Haul-off machine

5. Cutting machine

6. Board stacker

PVC foam board applications:

Transportation: boats, planes, buses, train cars, roof, core layer, interior panels.

Construction, decoration industry: building wall panels, interior decorative panels, residential, offices, public places and buildings interval, commercial decorative frame, clean room with a board, ceiling board, kitchenware, sanitary ware.

Advertising: screen printing, computer lettering, advertising signs, displays, signs with the board.

Industrial applications: chemical corrosion engineering, thermoforming parts, refrigerator with a board, special cold project, environmental protection, with the board.

Other uses: template, sports equipment, breeding materials, waterfront facilities, moisture, water timber, art materials, a variety of portable partitions.

Processing range: Thickness 1-20mm width 1200-2050mm

PVC foam board production line:

PVC foam board production line: