Electro Hydraulic CNC sychronised Press Brake

Model: PPBH 160T/4000 -DA52S

3 AXIS(X,Y1,Y2)

Bending Force: 1600Kn

Bending Length:3200mm on mild steel plate

Descriptions of CNC Synchro Press Brake:

cnc hydraulic Press brake Hydraulic system:

-A complete electrolyte servo synchro CNC (Computer Numerical Control) controlled press brake.

-Adopt Bosch electro hydraulic servo system (from Germany)

Mechanical system:

- Two light rulers are installed at the two ends of the slide, making the slide movement be parallel to the working table

- Adopt the working table compensation structure.

- The CNC servo motor of the back gauge gives a high positioning accuracy.

cnc hydraulic Press brake CNC system:

-Programming of the axes positions in tabular mode with automatic syntactical checks, automatic calculation of the bending and bending tonnage.

- All programs, tools description, parameters can be stored on the internal memory or on USB memory stick.

These files can be exchanged with other CNC and PC troughUSB memory stick.

- Complete graphic off-line programming on a standard PC, through a simulation program.

- Customizable alarm messages.

cnc hydraulic Press brake Synchro control system:

-Two light rulers (Y1-Y2) have been installed at the two sides of the machine to measure the exact distances.

-The position data will be delivered to the CNC system and then it can check out the servo valve control signal (S2-S2).

Transmission system:

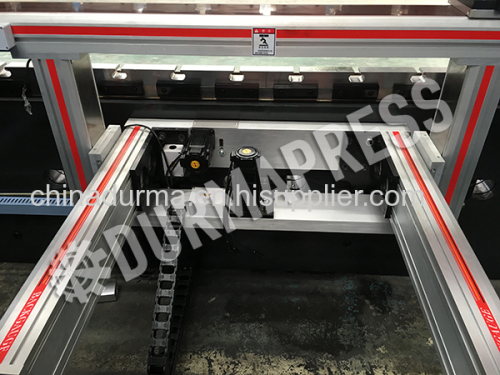

- High-precision ball screw and linear guide-way

- PANASONIC HINAS A4 series; AC servo motor and drive;

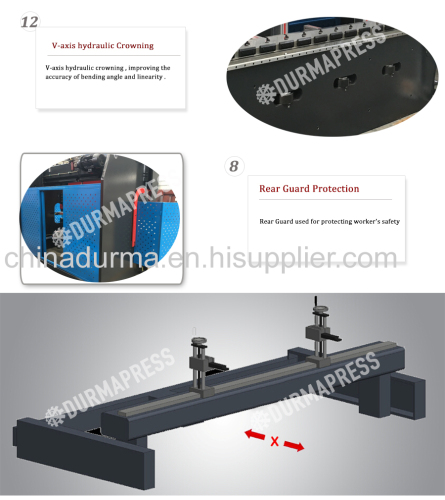

CNC hydraulic Press brake Compensation System:

-WILA deflection compensation;

-Automatic worktable compensation for wear and tear of the bed

The deviation resistance ability of the machine tool:

-The electrolyte servo system of this forging machine is an inner closing ring control system, which can check out the synchro discrepancies of the slide by the movement of the light ruler.

-The electrolyte servo valve can correct the slide discrepancies, making the slide parallel to the working table.

Key Components Made by:

No. | Item | ORIGIN |

1 | CNC Controller | ESA KV S530, Italy |

2 | Servo Motor and Drive | YASKAWA, Japan |

3 | Hydraulics | HOERBIGER Or BOSCH, Germany |

4 | Ball Screw | HIWIN, Taiwan |

5 | Linear Way | HIWIN, Taiwan |

6 | Hydraulic Fittings | EMB Fitting Type |

7 | Hydraulic Seals | Japan NOK |

8 | Linear Scale | GIVI, Italy |

9 | Electric Components | European/Japan |

Our Services

1.)- we can send our engineer to your site and do the training for your men. you will only bear the cost for our engineer's air ticket,visa,accormmadation,eating and transpotaion in your country

2.)-You can send your men to our factory. we will teach them how to operate the machine with no training charges

3. )-Actually there is another cheap and easy way to choose. every machine leave our factory with one book of operation manual.

You can first read through the manaul,and get familiar with the machine. Then we can get a video call,and teach you on-line how to operate the machine.

Apart from above training course,we also provide 2 year warranty for all the easily broken part of the machine

FAQ

No.1 How about your machine quality?We are worry about the quality.

RE: DURMAPRESS is a mature brand in CHINA,through our 30 years research in technology,our design including structure and detailed sercurity and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry ,there are Bohai machines.And where there are our machines,there are good reputation and terminal user satisfaction.

No.2 Whether the machine price can be more discount?

RE: 1.DURMAPRESS always provide high quality machine,as we know ,oversea market is more important and difficult than domestic market because of communication time costing after sales,So always,our machine has enough qaulity standard to make sure the machine can work more than the real warranty period.In this way ,we will save a lot and think in advance for the clients.

RE:2. Actually DURMAPRESS also think about our price level,we are sure to provide quality=price and pice=quality ,the matched price and acceptable for the clients and durable for our machines.We welcome your negotiate with us and get a good satisfaction.

No.3 How about your manufactory in CHINA

RE: DURMAPRESS located in Shanghai CITY, who is the biggest city in China with very convenient transportation ,We have worked about 25 years in this area and totally have about 300 staffs.Rich experience in this field with professional technical supporting and oriented service.

No.4 Where is your factory located? How can I visit there?

RE: DURMAPRESS factory is located Maanshan city ,anhui province,China.You can fly to Hongkou airport directly.It will take 40 minutes by car from the air port to our factory. All our clients, from home or abroad, are warmly welcome to visit us!

Durmapress Sales team and culture :