Step-transmit conveyor (Seven steps carcass processing and conveying machine)

Specifications

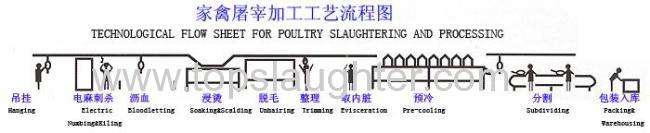

slaughter line

stainless steel made

adjustable length

It is used in cattle slaughter plant or beef cattle butchering house. Our company can design five, six or seven workstation conveyors according to customers different requirements. This machine can help to finish beef processing operations like pre-peeling, head cutting, peeling, evisceration, half-parting, trimming, quarantine etc.

Product features

1. Steady in running and high efficiency;

2. Highly automated, easy operating;

3. Easy in maintaining.

Technical Parameter

Motor power | 2.2kw |

Linear velocity | 12m/min |

Workstation spacing | 2400m |

Leg supporting spacing | 0.8m |

Run time | 12S |

Stop time | 0-3min(adjustable) |

Rating air pressure | 0.8Mpa |

Working air pressure | 0.6Mpa |

Tube rail | Φ60x5 |

Height (tube to ground) | 3.6-3.8m |

Size | Lx1270x1820 |

Maintenance

1. It requires professional operator.

2. There are oil containers on the both two ends of chain wheel. Oil adding times should be not less than twice each shift.

3. Oil within the cycloidal reducer should be on the middle line of the oil leveler. Changing oil every 300 hours at the first time, later every six months.

4. Operators should check switch sensitivity in the electrical and pneumatic parts regularly. Fixing and changing timely, if there is something wrong with it.

5. Taking overhaul maintenance in the production off-season every year.