Benefits of SPC

SPC rigid vinyl flooring is quickly becoming one of the most popular trends in home flooring. Installing SPC vinyl flooring offers the following benefits to homeowners:

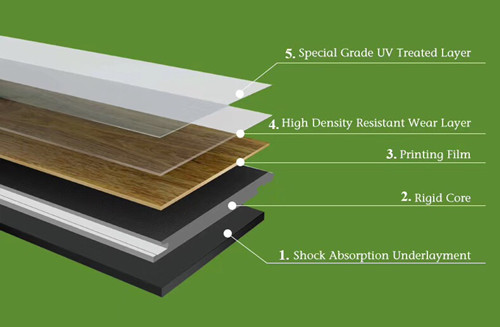

· Waterproof: One of the biggest benefits of choosing SPC vinyl flooring is that it has a completely waterproof core. Unlike hardwood, it can be installed in areas of the home such as laundry rooms, bathrooms, basements, and kitchens. The waterproof feature also makes this board more stable in environments where moisture and temperature can fluctuate.

· Easy installation: Many homeowners appreciate that SPC floors are easy to install. They can be placed on top of many different types of subfloors or existing flooring. Most designs simply click into place, eliminating the need for messy and complicated glues.

· Affordability: While it is more expensive than standard vinyl flooring, SPC vinyl floors are generally less expensive that other types of luxury flooring, such as hardwood and stone. In addition, homeowners can often install the floors without professional assistance, so DIY installation of SPC flooring can save even more money on this upgrade.

· Style: SPC vinyl flooring is like standard vinyl in that it is available in a wide range of colors and patterns. Some of the SPC flooring styles are designed to look like hardwood, tile, or other types of flooring. The wide range of options is preferable for those who want to be able to customize the look of their home.

· Comfort: The thick, stable bottom layers of each plank make SPC flooring more cushioned than other types of flooring. The thicker the plank you choose, the more comfortable it will feel underfoot. These dense layers also contribute to a quieter sound when walking on SPC floors; they usually do not have a hollow or thin sound like standard vinyl often does.

· Easy maintenance: SPC rigid vinyl flooring is very durable. Because it is incredibly dense, it's resistant to impacts, stains, scratches, and wear and tear. This flooring style is a great choice for busy households because in addition to holding up well, it is easy to keep clean. Maintenance involves only regular vacuuming or sweeping and occasional mopping. Over time, this type of flooring will resist fading, peeling, and cupping, and it can withstand being directly exposed to sunlight.

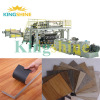

SPC floor is extruded by extruder and T-die , with four-roll or five-roller calender, respectively, PVC wear layer, PVC color film and PVC substrate, one-time heating paste, embossed products , The process is simple, close by heat to complete, do not need glue.

SPC Floor Extrusion Machine Options:

| SPC Flooring Machine | Conical twin screw extruder | parallel twin screw extruder | |||

| Model | 92/188 | 110/220 | 115 | 136 | 160 |

| Thickness(mm) | 2-8 | ||||

| Width(mm) | 1050,1350 | ||||

| Extruder motor(kw) | 110 | 200 | 90 | 160/200 | 250 |

| Output | 15ton/24h | 30ton/24h | 18-22ton/24h | 40-45ton/24h | 60-65ton/24h |

What machines required for the SPC floor plank?

Step 1: Material mixing and recycling

Hot-cold mixing machine, crusher and milling machine.

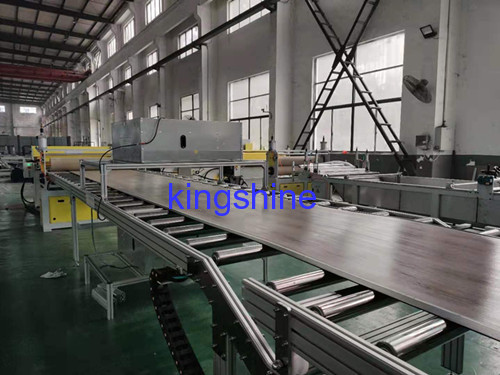

Step 2: Extrusion (laminting&embossing):

SPC floor extrusion line

Step 3:UV Coating

UV coating machine

Step 4:Cutting& Slotting

Cutting and slotting machine

Step 5: V shape groove UV coating (optional)

V-groove coating machine

Step 6: Underlayer laminating

Hot glue laminating machine

About Us

Jiangsu Kingshine Plast Machine Co.,Ltd is one of the most professional plastic machinery manufacturing enterprises in China. The main production is SPC/LVT floor extrusion machine, PVC sheet extrusion machine, PVC/WPC door board/frame extrusion machine, PVC laminating/marble sheet extrusion machine, ect. Kingshine pay attention to technological innovation, actively introduce advanced foreign technology, and constantly develop new products.

Kingshine supply SPC floor production line not only machine but also formula and technology, help customer start the project with professional servic.

Our advantage:

European Standard Machines

On-line EIR technology which is our patent technology.

The most advanced parallel 136 stable using in market

Special Five-roller calender (Patent)

We participated the 5 years SPC floor development. We are always on the road of R & D and keep leading position.

We have large customer base in China, from which we get lasted news about SPC floor, we get demand, find problems, improve problems, test and verify new technology, to keep our machine stable running, meet customer's demand, and keep our machine the most advanced.

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Contact:

Joy Zhang

Int'l Sales Manager

Mobile/Whatsapp: +86 13405773767

Skype/Wechat: yizhang28